Dave Cook and Ian Stewart

Rail electrification has been implemented in many urban and regional rail applications in the US and the benefits are numerous. Electrified rail is quiet, quick, clean and generally more reliable and less expensive to operate than similar services with Diesel fueled locomotives. There are significant environmental benefits as well, with the elimination of local release of NOx, diesel PM and other criteria emissions by the train and reduction of overall greenhouse gas emissions by acquiring electricity from stationary power plants where it is generated more efficiently. Further, most current electrified rail is able to capture some of the trains’ energy ( ~30% ) when braking, with several examples demonstrating wayside energy storage capable of capturing most of the train’s braking energy. So why haven’t all regional rails been electrified. The most fundamental reason is the initial cost.

With the average cost for conversion to electrified rail being $10 million dollars per route mile for infrastructure and new equipment. For example, the 49 miles of CalTrain peninsula route currently slated for electrification is expected to cost $600 million or more, which is $12.25 Million per mile. Other challenges of electrification involve lengthy and complex integration of the electrified infrastructure, disruption of operations during construction and the inherent limitations of dedicated catenary wires or an electrified third rail to provide the power to propel the train. Conversion requires a shift in expectations for the train service. If the power is out in an emergency so is the train and when the catenary or electrified rail ends so does the train service. These limits on the use and versatility of electrification must be weighed against operation with conventional Diesel Electric Locomotives that are internally powered, and can run on any existing rail line. This is a difficult tradeoff for agencies as the conventional locomotive solution is widely accepted and perceived by the industry as preferred given the lower initial cost and greater versatility. The challenges to full electrification have agencies looking to incrementally improve existing diesel equipment or purchase new diesel passenger locomotives rather than risking conversion.

Of course, retaining the existing diesel solutions also retains the associated higher operating and maintenance costs, lower reliability, and most of all, higher levels of NOx and PM emissions as compared to equivalent electrified system. The current trend is for agencies to purchase new high speed (125mph) locomotives. These new locomotives are excellent for long distance applications with few stops, but what regional passenger agencies need is quickness, not speed. It would take 800 extra horsepower and 13 miles to accelerate today’s Pacific Surfliner to 110 miles per hour. If the distance between the majority of the regional rail stations in the US is less than 6 miles, the train typically does not have sufficient power and distance to even briefly achieve 90 mph, so why does it need to be capable of traveling at 125 mph? The key to efficient regional rail is quickness, not high speed, and what is needed is a new approach.

Enter the ZEBL (Zero Emissions Booster Locomotive)

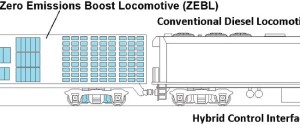

What if there was a way to retain the best features of electrified and conventional diesel electric regional rail service? What if it was possible to introduce electrification and the corresponding improvements in performance and efficiency to an existing regional route incrementally while retaining the versatility and reliability of the conventional locomotives? Enter the ZEBL, a new type of hybrid locomotive that is simply added into the existing train consist. The ZEBL is not a replacement, it is an enhancement attached behind an existing locomotive and connected with a small interface controller, resulting in a Hybrid Pair. The Hybrid Pair increases acceleration while consuming less fuel and thus reducing emissions relative to the conventional locomotive alone. The ZEBL provides a ‘plug and play’ hybrid solution for existing regional trains making them quicker; allowing them to attain the same or greater average speed as the conventional regional train on a given route with a fraction of the fuel consumed and emissions produced. For example, this chart illustrates the difference in performance between the current Caltrain regional train going from San Francisco to San Jose and a ZEBL hybridized version of the same train:

What if there was a way to retain the best features of electrified and conventional diesel electric regional rail service? What if it was possible to introduce electrification and the corresponding improvements in performance and efficiency to an existing regional route incrementally while retaining the versatility and reliability of the conventional locomotives? Enter the ZEBL, a new type of hybrid locomotive that is simply added into the existing train consist. The ZEBL is not a replacement, it is an enhancement attached behind an existing locomotive and connected with a small interface controller, resulting in a Hybrid Pair. The Hybrid Pair increases acceleration while consuming less fuel and thus reducing emissions relative to the conventional locomotive alone. The ZEBL provides a ‘plug and play’ hybrid solution for existing regional trains making them quicker; allowing them to attain the same or greater average speed as the conventional regional train on a given route with a fraction of the fuel consumed and emissions produced. For example, this chart illustrates the difference in performance between the current Caltrain regional train going from San Francisco to San Jose and a ZEBL hybridized version of the same train:

The red line indicates the conventional train performance with only a diesel locomotive accelerating it and the green line illustrates the hybridized train performance using a single ZEBL. (Note that only at the longest segment at 4.06 miles can Caltrain actually achieve the 79 mph speed limit on this route.) The hybrid train accelerates much more rapidly due to its additional traction motors. With the improved acceleration rate, the hybrid train has a lower peak speed and spends less time at full throttle on the diesel engine. For the same schedule, the hybridized train will cover the Caltrain route in the same time while consuming 50% less energy. Observe how much longer the conventional diesel train has to run at full throttle up to the peak of the red line and compare it to how quickly power can be reduced in the hybridized train as the green line peaks and the train cruises at a lower peak speed. This is where the dramatic energy savings is found. The current Caltrain schedule would allow for 6 hybridized trains to perform 4 round trips a day. Each of these ZEBL hybridized trains could save the agency $450,000 per year in fuel costs in addition to significant cost savings from the minimal use and maintenance of the passenger car and locomotive air brakes.

The different technologies that make up the ZEBL and the resulting hybridized train are proven and currently in field service. They have been made viable by the recent maturation of economical, efficient, high power electronics and ultra capacitors, and the growing fleets of hybrid transit buses using them. What is new is the application, interaction and integration of these technologies for regional passenger train hybridization. The ZEBL provides the energy-capture, storage and release capabilities thought to only be available through full electrification and allows them to be applied easily to conventional regional train use.

While the ZEBL Hybridized regional train enables significant reductions in fuel consumption and emissions, it still lacks a vital feature that is inherent in fully electrified systems: connection to the grid. This lack results in excessive reliance on the diesel locomotive to supply the energy necessary to accelerate the train. Inductive power transfer, a recent advancement in the rapidly evolving technology of wireless charging systems for electric cars and buses, can be easily incorporated on the ZEBL Hybridized train. If a ZEBL equipped regional train and the train stations on its operating route were equipped with a Wireless Power Transfer System (WPTS), the ZEBL could be charged at each station. By adding the ability to transfer and store 20kW-hrs of energy at each stop, the fuel use reduction would be increased from 50% to 72%. Also, equipping a train with a WPTS-enabled ZEBL allows it to be parked for extended periods without needing to run the diesel fueled HEP generator.

The addition of WPTS to the ZEBL hybridized train can, again, be accomplished incrementally, train by train and station by station with minimal infrastructure change and interruption in service. With the underside of two locomotives able to wirelessly transfer power, the train is capable of receiving 90% or more of its energy from the grid, while still having on board fuel storage (CNG or Diesel) for when the electric grid load needs to be reduced during peak demand, long segments where full electric operation is not practical or if the grid goes down during an emergency. If the engine on the lead locomotive is configured with emissions reduction technologies such as natural gas fuel and after treatment systems, the resulting hybridized train becomes a Near Zero Emissions equivalent to fully electrified trains.

The hybrid regional train concept is the work of Rail Propulsion Systems (RPS). RPS is a California based company, ready to demonstrate that the addition of a ZEBL can provide:

- Hybrid electrification of regional passenger rail at a fraction of the cost and disruption of conventional electrification.

- Seamless connection to the electric grid incrementally with a simple non invasive station by station transition.

- Ability to integrate with the main electric grid as a microgrid to balance periods of low or peak demand.

- Retention of the existing locomotive, allowing the train to continue to operate with or without power from the

- grid.

Imagine the Acceleration, Efficiency, and Zero Emissions benefits of Electrified Regional Rail without:

- Unsightly catenary wires or dangerous third rail

- $10,000,000+ per mile conversion cost

- Restriction of operating on dedicated electrified track

For regional rail, quickly accelerating and decelerating a train between stations enables the fastest operation. Capturing the braking energy and reapplying it during acceleration allows this to be done with the least amount of fuel and/or electricity consumed. To accomplish this, we must add energy storage and additional tractive force to the existing train. In short, the time has come to hybridize existing regional trains.

The authors can be contacted at:

[email protected], [email protected].

Download a PDF copy of this report.